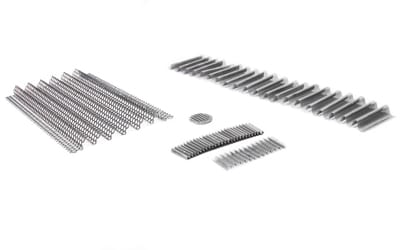

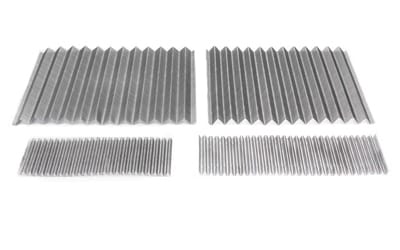

- Custom Parts

- Parts Gallery

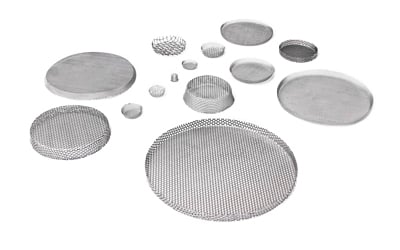

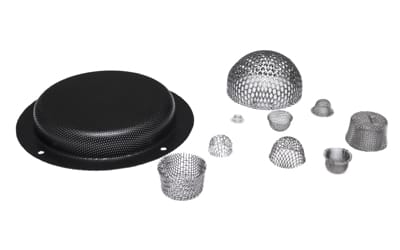

- Basket Style Hydraulic Oil Strainer

- Refueling Filter

- Oil Pan Filter

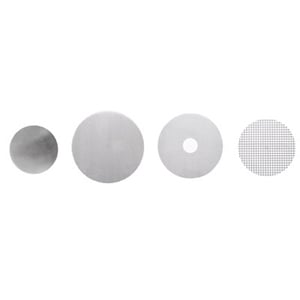

- Corrosion Resistant Stainless Steel Filter

- Perforated Stainless Steel Filter

- Vacuum Pump Filter

- Perforated Brass Filter

- 30 Mesh Stainless Steel Filter

- Tank Filter

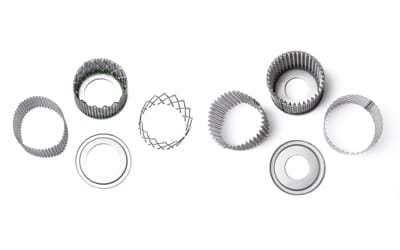

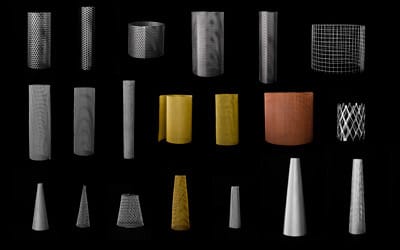

- Pleated Stainless Steel Filter

- Dutch Weave Stainless Steel Filter

- Perforated Steel Motor Housing Guard

- Stainless Steel Filter

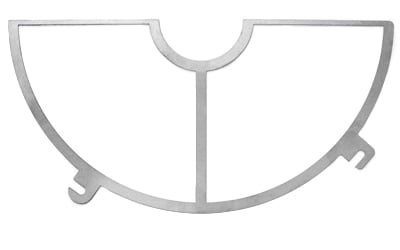

- Transmission Fluid Screen

- Cryogenic Stainless Steel Filter

- Perforated Bag Fold Filter

- Capabilities

- Design Assistance

- Industries

- FAQs

- About Us

- Contact Us

.jpg?width=400&name=resistancewelding_resized%20(1).jpg)